The Significance of PCD Tooling in Modern Manufacturing

Share

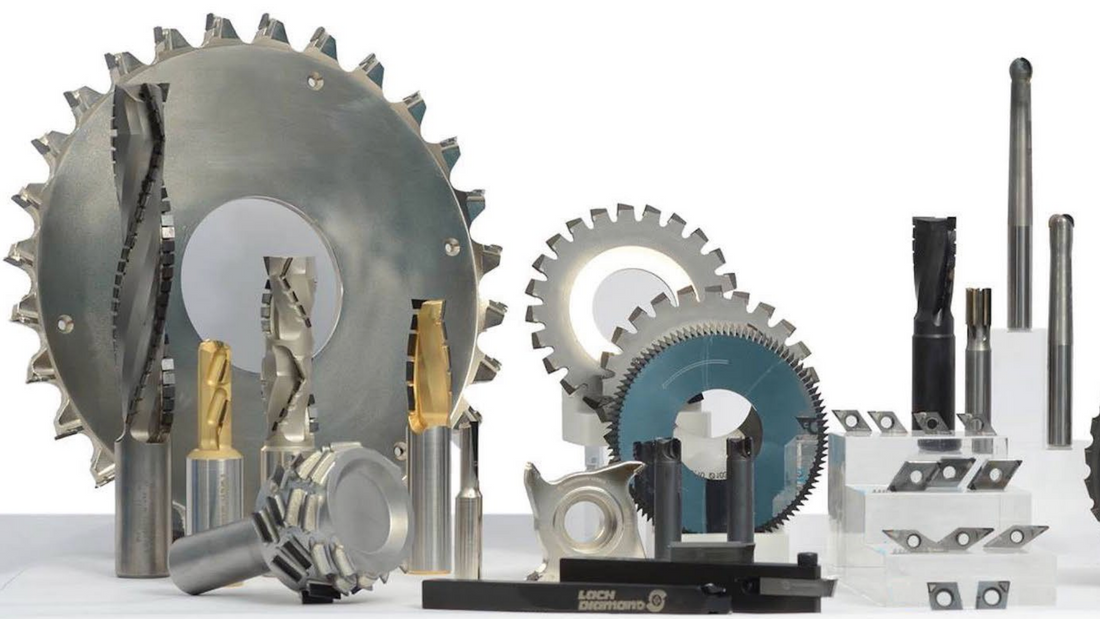

Polycrystalline diamond (PCD) tooling has emerged as a game-changer across various industries, particularly in woodworking, automotive, wind power, electric motor manufacturing, circuit boards, and printing. Its unique properties make it an invaluable asset for manufacturers seeking to enhance efficiency and product quality.

Advantages of PCD Tooling

One of the most compelling advantages of PCD tooling is its high efficiency and productivity. The material's hardness allows for faster cutting speeds, which translates to shorter cycle times and increased output. This is particularly beneficial in woodworking, where precision and speed are paramount.

Moreover, PCD tools feature extremely stable cutting edges that maintain their sharpness over extended periods. This stability not only reduces the frequency of tool changes but also minimizes downtime, allowing manufacturers to focus on production rather than maintenance. The extended tool life associated with PCD tooling means that businesses can achieve significant cost savings over time.

Quality of Finish

In addition to efficiency, PCD tooling excels in delivering a superior finish quality. The smooth operation of these tools results in a refined surface finish, which is crucial in woodworking applications where aesthetics and precision are essential. The ability to maintain high feed rates without compromising on finish quality further enhances the appeal of PCD tools.

Versatility Across Industries

The versatility of PCD tooling extends beyond woodworking. In the automotive sector, for instance, PCD tools are used for machining complex components with tight tolerances. In wind power and electric motor manufacturing, they facilitate the production of high-performance parts that require durability and precision. Similarly, in the realm of circuit boards and printing, PCD tooling ensures that intricate designs are executed flawlessly.

Conclusion

As industries continue to evolve, the demand for high-performance tooling solutions will only grow. PCD tooling stands out as a reliable choice for manufacturers aiming to boost productivity, enhance product quality, and reduce operational costs. By considering the advantages of PCD tools, businesses can position themselves for success in an increasingly competitive landscape.