Caring for Industrial Woodworking Tooling: A Comprehensive Guide

Share

In the world of industrial woodworking, the longevity and performance of your tooling can significantly impact productivity and quality. Proper care and maintenance of saw blades, profile tooling for CNC routers, moulders, shapers, and knives for planers and jointers are essential. This article will provide you with essential tips on storage, cleaning, handling, and extending the life of your tools, while also addressing safety concerns and when to sharpen your tooling.

Storage Tips for Tooling

Cutterheads with Brazed Tool Tips

Cutterheads with brazed-on tool tips require special attention during storage. Always store these tools in a dry, clean environment to prevent rust and corrosion. Use protective cases or racks to keep them organized and avoid contact with other tools that could cause damage. Ensure that the cutting edges are not exposed to prevent accidental nicks or dulling.

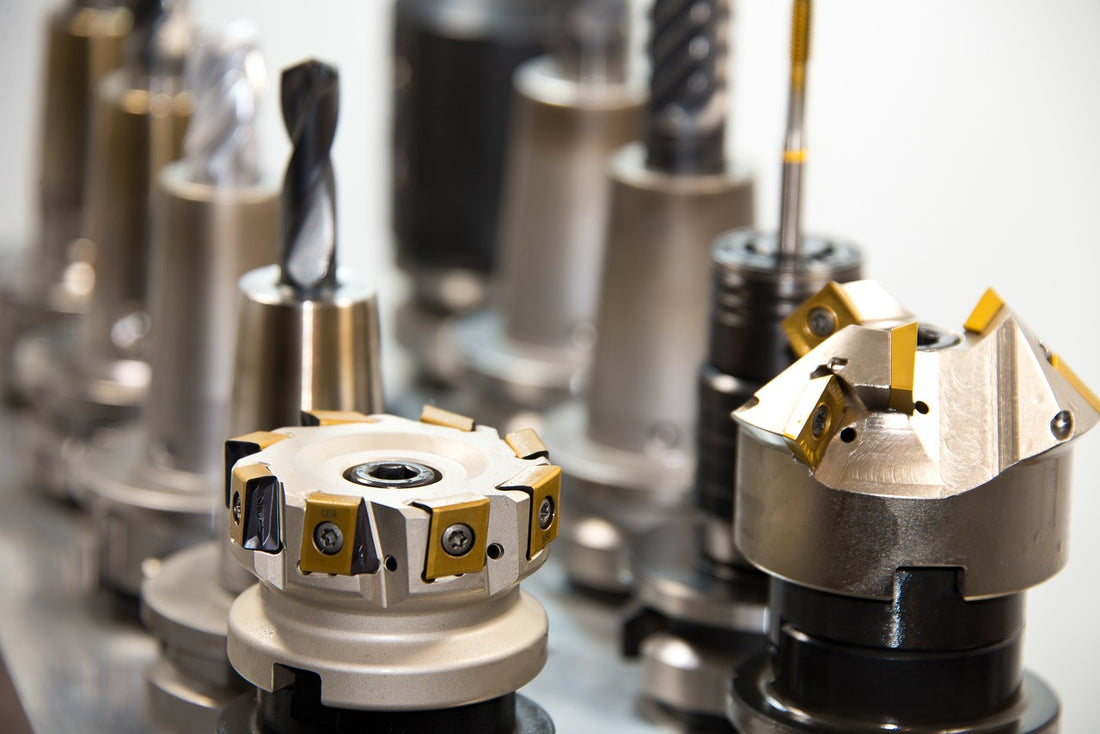

Insert Tooling

Insert tooling, which can be separated from the cutterhead, should be stored in designated containers that prevent movement and contact with other tools. Use labeled compartments to keep different inserts organized and easily accessible. This not only protects the inserts but also helps in maintaining an efficient workflow.

Proper Cleaning and Handling

Steel, Carbide, and Diamond Tooling

Cleaning your tooling after each use is crucial for maintaining performance. For steel tools, use a soft brush or cloth to remove sawdust and debris. A mild solvent can be used for deeper cleaning, but ensure that the tool is completely dry before storage to prevent rust.

Carbide tooling requires similar care, but be cautious with solvents that may damage the bonding agents. A gentle cleaning solution and a soft cloth are usually sufficient. For diamond tooling, avoid abrasive cleaners. Instead, use a soft brush and water to clean the surface, ensuring that no residue remains.

Safety Considerations

Always wear appropriate personal protective equipment (PPE) when handling tooling. This includes gloves to protect your hands from sharp edges and safety glasses to shield your eyes from debris. When cleaning or sharpening tools, ensure that the workspace is clear of hazards to prevent accidents.

Extending the Life of Your Tools

- Regular Maintenance: Schedule regular inspections of your tooling to identify wear and tear early. This proactive approach can prevent costly replacements.

- Proper Usage: Always use the right tool for the job. Overloading or misusing tools can lead to premature wear and damage.

- Sharpening: Keep your tools sharp. Dull tools require more force to cut, which can lead to overheating and damage.

- Environmental Control: Store tools in a climate-controlled environment to minimize exposure to moisture and extreme temperatures when not in use.

When to Sharpen Tools

Knowing when to sharpen your tools is key to maintaining their performance. Signs that your tooling needs sharpening include:

- Increased resistance when cutting

- Rough or uneven cuts

- Burn marks on the wood

- Excessive noise during operation

If you notice any of these signs, it’s time to consider sharpening your tools. Regularly scheduled sharpening can also help maintain optimal performance and extend the life of your tooling.

Connecting with Qualified Tool Repair and Sharpening Services

For those who prefer professional assistance, we offer connections to qualified tool repair and sharpening services for your steel, carbide, and diamond tooling. These experts can ensure that your tools are sharpened correctly and maintained to the highest standards, allowing you to focus on your woodworking projects.

In conclusion, proper care and maintenance of your industrial woodworking tooling are essential for ensuring longevity and performance. By following these tips on storage, cleaning, handling, and sharpening, you can keep your tools in top condition and enhance your woodworking experience. Remember, a well-maintained tool is not just an investment in your equipment, but also in the quality of your work.